Double Row Tapered Roller Bearing

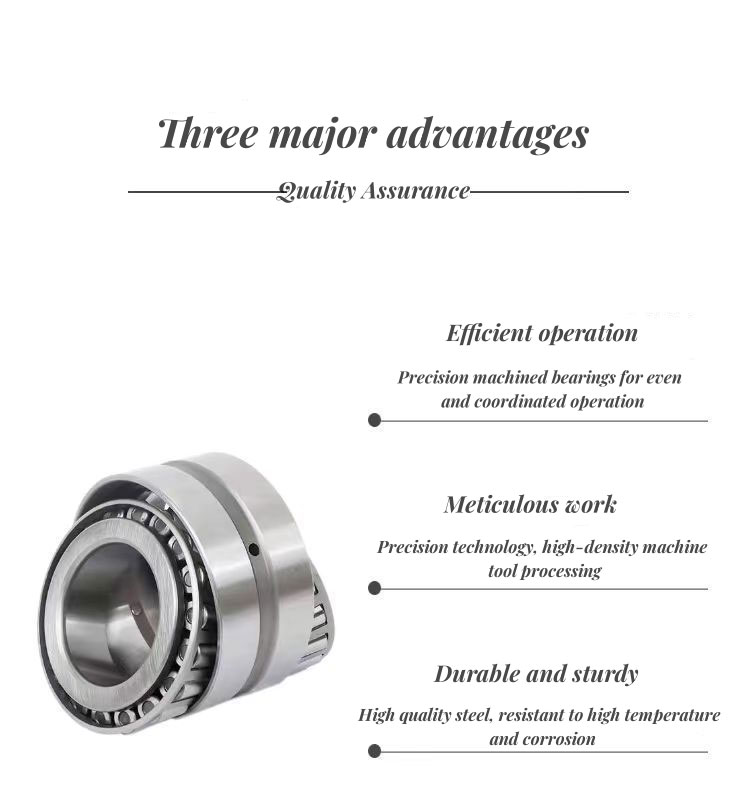

Yinchi double row tapered roller bearing is a widely used bearing type. Its working principle allows two tapered rollers to rotate synchronously between the inner and outer rings of the bearing, providing excellent axial and radial support. This bearing has high load-bearing capacity and compact volume, making it particularly suitable for harsh working environments such as high speed, heavy load, and high temperature. The key to its working principle lies in the unique geometric shape and motion characteristics of the tapered roller. Through precise geometric design, the Yinchi double row tapered roller bearing has achieved high precision and long service life. This makes the bearing an ideal choice for various industrial applications, ensuring stable machine operation and extending service life.

Send Inquiry

Product Description

Double Row Tapered Roller Bearing

Yinchi double row tapered roller bearing is a widely used bearing type. Its working principle allows two tapered rollers to rotate synchronously between the inner and outer rings of the bearing, providing excellent axial and radial support. This bearing has high load-bearing capacity and compact volume, making it particularly suitable for harsh working environments such as high speed, heavy load, and high temperature.

The key to its working principle lies in the unique geometric shape and motion characteristics of the tapered roller. Through precise geometric design, the Yinchi double row tapered roller bearing has achieved high precision and long service life. This makes the bearing an ideal choice for various industrial applications, ensuring stable machine operation and extending service life.

For more information, please visit us: https://www.sdycmachine.com/

|

brand |

Yinchi |

|

Bearing material |

High carbon chromium bearing steel (fully quenched type)(GCr15) |

|

Chamfer |

Black Chamfer and Light Chamfer |

|

Noice |

Z1, Z2, Z3 |

|

Delivery Time |

7-35 Days as Your Quantity |

Double row tapered roller bearings are a multifunctional and efficient bearing type that can withstand combined axial and radial loads. Its unique design places two rows of tapered rollers in the tapered guide groove, optimizing the bearing's load-bearing capacity and efficiency. This design effectively extends the service life of bearings and improves their reliability by reducing axial and radial friction as well as heat generation.

This type of bearing is widely used in various industrial fields, especially in harsh working conditions such as high load, high speed, and high temperature. Its excellent performance and stability make double row tapered roller bearings a core component in many critical equipment, providing strong support for ensuring reliable operation and extending service life of the equipment.

For more information, please visit us: https://www.sdycmachine.com/