Tapered Roller Bearing for Reducer

The Tapered Roller Bearing for Reducer used in the Yinchi reducer have a series of technical specifications, as follows: Bearing model: For example, 30212. Bearing inner diameter: For example, 60mm. Outer diameter of bearing: e.g. 110mm. Bearing thickness: For example, 28mm. Bearing material: High quality high carbon chromium steel. Bearing type: separable. Sealing method: double-sided sealing. Lubrication method: oil lubrication or grease lubrication. Application environment: Suitable for harsh conditions such as heavy loads, high speeds, and high temperatures. Installation method: Pressure fitting or thermal expansion can be used for installation.

Send Inquiry

Product Description

Tapered Roller Bearing for Reducer

The tapered roller bearings used in the Yinchi reducer have a series of technical specifications, as follows:

Bearing model: For example, 30212.

Bearing inner diameter: For example, 60mm.

Outer diameter of bearing: e.g. 110mm.

Bearing thickness: For example, 28mm.

Bearing material: High quality high carbon chromium steel.

Bearing type: separable.

Sealing method: double-sided sealing.

Lubrication method: oil lubrication or grease lubrication.

Application environment: Suitable for harsh conditions such as heavy loads, high speeds, and high temperatures.

Installation method: Pressure fitting or thermal expansion can be used for installation.

These technical specifications are common and may vary depending on different reducers and operating conditions. When selecting suitable bearings, it is important to choose based on the specific requirements and working conditions of the reducer to ensure optimal performance and reliability.

For more information, please visit us: https://www.sdycmachine.com/

|

Load Capacity |

Radial load mainly |

|

Precision Rating |

P0 P6 P5 P4 P2 |

|

Bearing Vibration |

Bearing Vibration |

|

Lubrication |

Grease or Oil |

|

Material |

Chrome Steel GCr15 stainless steel/ carbon steel |

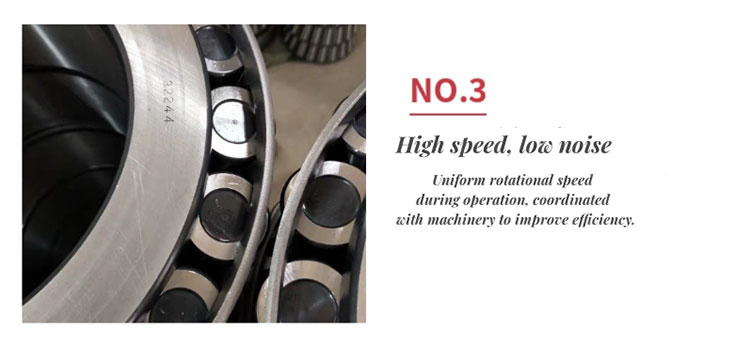

The tapered roller bearing in the reducer is the core component, and its technical implementation path includes several key links. Firstly, selecting the appropriate type of tapered roller bearing is crucial. This requires selecting the appropriate bearing model and size based on the operating speed, load capacity, and accuracy requirements of the reducer. Secondly, the installation and adjustment of bearings are the foundation for ensuring their stable operation. This step requires precise operation to achieve accurate installation of bearings in the reducer. Finally, proper lubrication and maintenance of bearings are key measures to ensure their normal operation and service life. By implementing these steps, it is possible to ensure the optimal performance of tapered roller bearings in reducers and extend their service life.

For more information, please visit us: https://www.sdycmachine.com/