Tapered Roller Bearing Machinery

Introduction to Yinchi tapered roller bearing machinery Conical roller bearings play a crucial role in various industrial applications, ensuring smooth and efficient rotation. This mechanical equipment has a unique design and is suitable for handling high-speed rotation under high loads, making it an ideal choice for many rotating machinery. The main advantages of tapered roller bearings are their ability to bear radial and axial loads, high stiffness, and excellent durability. Its conical design makes assembly and adjustment simple, while ensuring stability under heavy loads. In addition, the mechanical bearings have various sizes and configurations to choose from, which can meet the needs of various specific applications.

Send Inquiry

Product Description

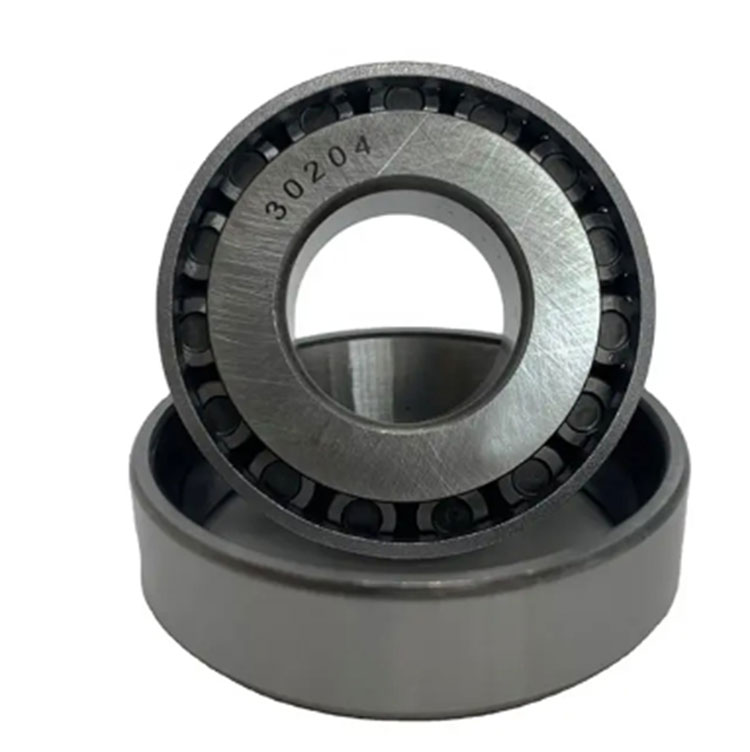

Tapered Roller Bearing Machinery

Introduction to Yinchi tapered roller bearing machinery

Conical roller bearings play a crucial role in various industrial applications, ensuring smooth and efficient rotation. This mechanical equipment has a unique design and is suitable for handling high-speed rotation under high loads, making it an ideal choice for many rotating machinery.

The main advantages of tapered roller bearings are their ability to bear radial and axial loads, high stiffness, and excellent durability. Its conical design makes assembly and adjustment simple, while ensuring stability under heavy loads. In addition, the mechanical bearings have various sizes and configurations to choose from, which can meet the needs of various specific applications.

The application range of Yinchi tapered roller bearing machinery is wide:

Rotary table in machine tools

Main shaft and transmission shaft in rolling mill

Rotating shafts in pumps and fans

High speed turbocharger

Rotating brackets in conveyors and elevators

By choosing high-quality tapered roller bearing machinery, you can ensure the stable operation of industrial equipment, extend its service life, thereby improving production efficiency and reducing maintenance costs.

|

Advantage |

High precision pressure Resistance |

|

Lubrication |

Oil/Grease |

|

brand |

Yinchi |

|

Bearing material |

High carbon chromium bearing steel |

|

Applicable industries |

Communication equipment manufacturing |

|

Outer Dimension |

10-200mm |

|

Precision Rating |

P0/P6/P5/P4/P2 |

Cone roller bearing machinery is a high-precision, high load-bearing capacity bearing equipment widely used in various industrial fields. It adopts a unique tapered roller design to ensure excellent stability and reliability during high-speed operation.

This bearing has the following significant characteristics:

1. Compact structural design: Conical roller bearings can achieve large load-bearing capacity in limited space, making them widely used in various compact mechanical equipment.

2. Excellent load-bearing capacity: Due to the use of larger rolling surfaces, tapered roller bearings can better distribute loads and demonstrate excellent load-bearing performance.

3. Excellent high-speed performance: During high-speed rotation, the contact point between the roller and the inner and outer rings constantly changes, effectively reducing friction heat and improving the service life of the bearing.

4. Self centering function: The tapered roller bearing has the ability of self centering, which can automatically adjust even if there is slight misalignment during installation, ensuring the normal operation of the bearing.

5. Easy maintenance: Its structural design makes disassembly and replacement simple and convenient, making it easy for daily maintenance and upkeep.

In summary, tapered roller bearing machinery has become an ideal choice for various high-speed and heavy-duty industrial applications due to its high performance, high reliability, and other characteristics.